Whether you're troubleshooting an emergency or enhancing the safety and reliability of mission critical systems, we're ready to provide the professional inspection and analysis you need. More

- RoofingInfrared and Nuclear Roof Moisture Surveys

- Vector MappingElectronic Leak Detection in Roof and Waterproofing Membranes

- Building EnclosureSave Energy, Stop Drafts, Leaks and Mold, Cut Costs, Go Green

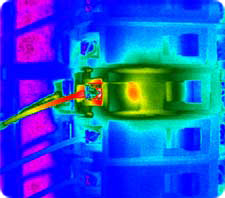

- ElectricalReduce Downtime and Risk, Save Money

- SteamCut Costs, Boost Steam System Efficiency